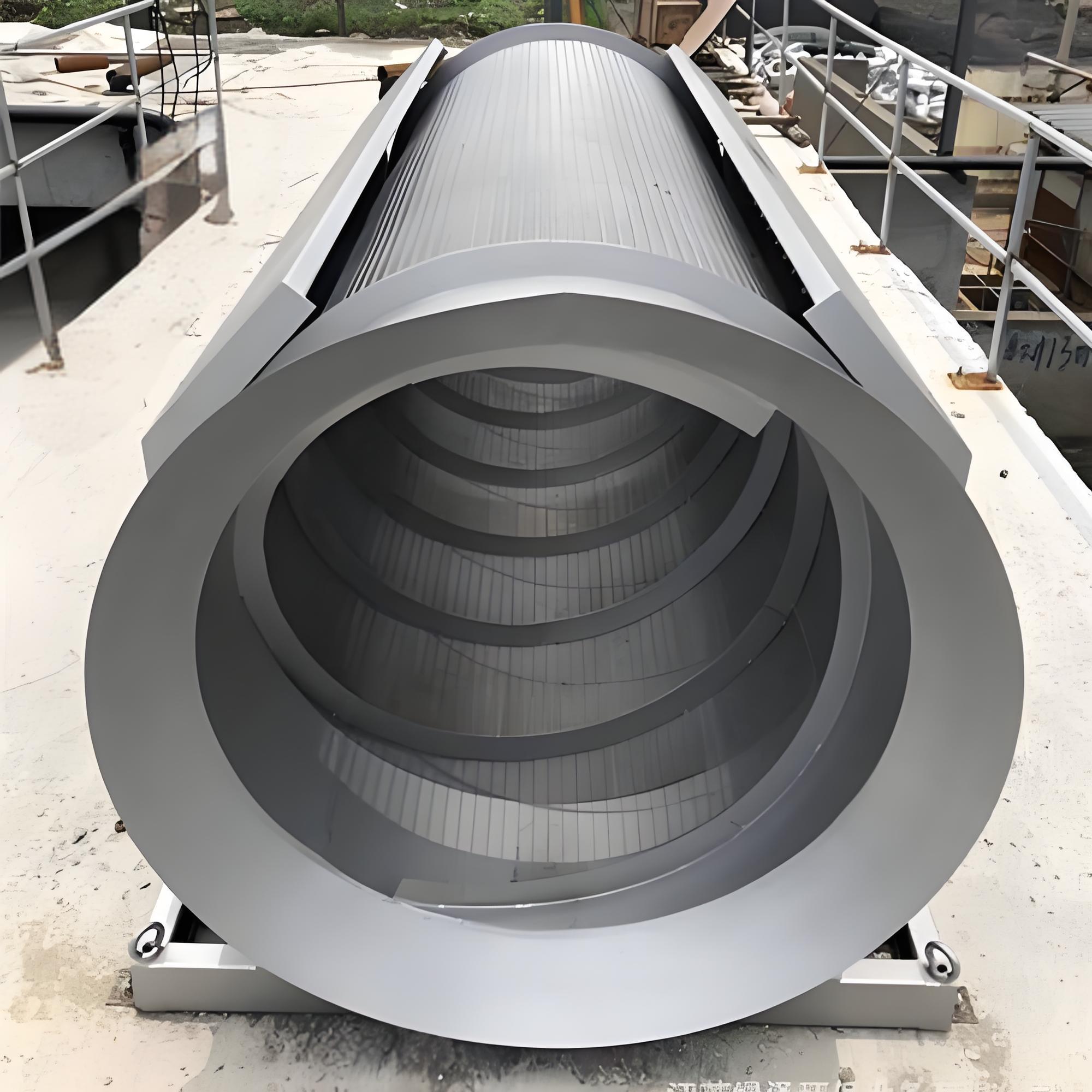

A microfilter is a solid-liquid separation device that uses a sieve or filter element to intercept suspended solids, colloidal particles, and other impurities in water.

Working principle

Filtration process: Sewage enters the microfilter drum along the axial direction and flows out through the sieve in a radial radiation pattern. Impurities in the water (such as fine suspended solids, fibers, pulp, etc.) are trapped inside the sieve. When impurities accumulate to a certain extent, they are flushed back into the slag discharge tank through pressure flushing water and flow out.

Backwash mechanism: The filter cartridge is equipped with a flushing water pipe, and the flushing water pressure is ≥ 4kg/cm ². It sprays in a fan shape to flush and clear the filter screen, ensuring that the filter screen always maintains good filtration capacity.

Equipment features

Efficient filtration: The filtration accuracy is between 0.1 and 50 microns, which can effectively remove small particles such as colloids, particles, and bacteria in water, and improve the purity of water quality.

Compact structure: small footprint, large production capacity (250-36000m ³/d), easy operation.

Stable operation: Fully automatic continuous operation, no need for dedicated supervision, with a maximum filtered substance concentration of over 12%.

Easy maintenance: The filter can be cleaned and regenerated, with a long service life, fewer vulnerable parts, no consumables, and low operating and maintenance costs.

Energy saving and Water saving: The backwashing process is short, and the backwashing water consumption is only 0.001-0.003% of the normal water production, saving water, electricity, and energy.

Application Fields

Industrial field: commonly used in the production of chemical, electronic, pharmaceutical, printing, food and other industrial fields to purify water quality and improve product quality. For example, in oil extraction and refining, removing sediment and impurities from crude oil; In refineries, filter suspended solids in cooling water and circulating water to prevent equipment scaling and corrosion.

In the field of daily life, it is used in household tap water purification, faucet filters, smart toilets, and other areas to effectively remove impurities and odors from water, ensuring people's drinking health.

In the field of agriculture, it is widely used in agricultural irrigation systems to filter out suspended substances in water, protect the growth environment of crops, and increase yields.

Aquaculture: In a recirculating aquaculture system (RAS), total suspended solids (TSS) in water are effectively removed, including feed residues, fish feces, dead aquatic organisms, sediment, etc., reducing organic load in the water; Reduce the organic load of biofilters and provide a more suitable growth environment for nitrifying bacteria; Improve the effectiveness of ultraviolet disinfection, allowing ultraviolet rays to better penetrate water and irradiate microorganisms in the water, thereby enhancing disinfection efficiency.

Environmental Protection and Resource Recycling: Used for water purification in urban rivers and scenic lakes, removing algae, floating debris, and sediment from water, improving water transparency, and restoring aquatic ecology; In the process of sludge treatment, as a pre-treatment equipment before sludge dewatering, it reduces the moisture content of sludge and improves the treatment efficiency of subsequent dewatering equipment; In the fields of leachate treatment and kitchen waste treatment, solid-liquid separation is achieved to extract valuable substances and achieve waste reduction and resource utilization.

Frequently Asked Questions

Poor filtration effect: clogged or damaged filter screens can lead to a decrease in filtration efficiency. When the filter is clogged, the resistance of water flow through the filter increases, the filtration speed slows down, and some impurities cannot be effectively filtered; When the filter screen is damaged, some larger particles and impurities that should have been filtered out will directly enter the water body, affecting the water quality.

Backwash system failure: Insufficient or excessive backwash intensity, automatic backwash sensor failure, insufficient water or air pressure, and other issues can all affect the backwash effect, thereby affecting the normal operation of the microfilter.

Motor malfunction: Motor overload, short circuit, and other issues may be caused by severe filter blockage, increased motor load, poor sealing of the casing, or insufficient waterproof rating of the motor.

PREV: No more

NEXT: Multi-media filter